About us

Who we are

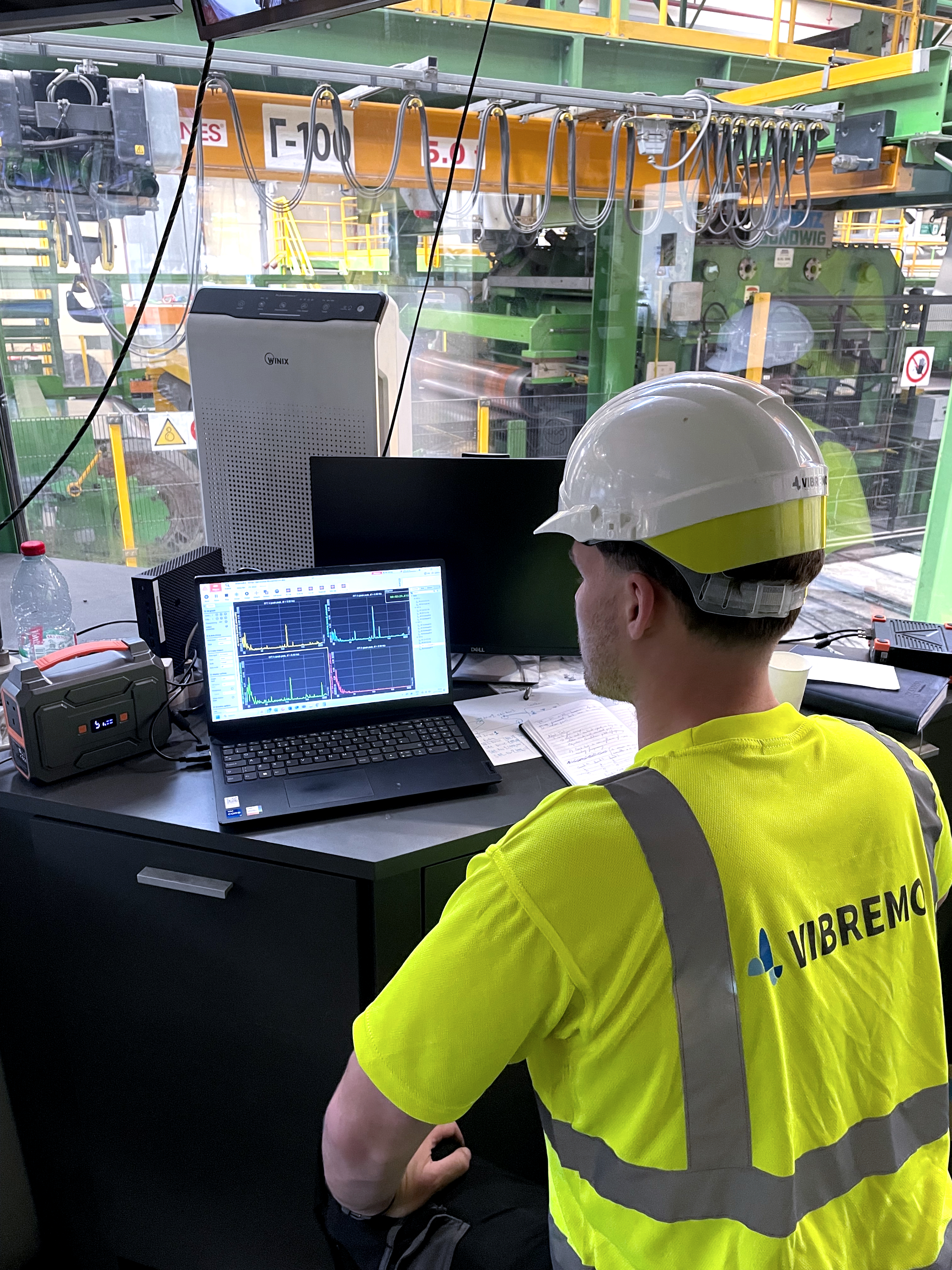

At Vibremo, we specialise in understanding and resolving vibration challenges in the rolled metals industry.

Our engineers work closely with aluminium and steel producers around the world to improve product quality, machine reliability and operational efficiency.

We combine practical field experience with advanced measurement technology and diagnostic expertise to help our clients reduce defect recurrence, improve efficiency and extend equipment life - from roll grinders and rolling mills to isolation systems and building structures.

What we do

Vibration in rolling and finishing operations can affect surface quality, product flatness and machine productivity. We carry out detailed on-site investigations and engineering analysis to identify root cause issues and recommend effective, sustainable solutions.

Every project is approached collaboratively. We work side-by-side with plant engineers and maintenance teams to ensure that solutions are practical, safe and aligned with production requirements.

Our services

Our services

Our approach

Experience & expertise

Our team has supported aluminium and steel plants across Europe, America, Asia and the Middle East, delivering vibration consultancy for both new installations and established production lines.

We have contributed to projects in a range of sectors including rolled metals, manufacturing, energy, and heavy engineering, and participated in R&D collaborations with universities and research partners focused on vibro-acoustics and structural dynamics.

This combination of on-site knowledge and research experience allows us to apply proven methods while staying at the forefront of vibration engineering practice.

Our approach

Our approach

High resolution operational data obtained under production conditions.

Resonance testing and modal analysis conducted to assess structural dynamics of machines.

1

On-Site Measurement

Advanced data analysis and modelling, characterising resultant vibration and identifying the root cause issues, leading to highly effective solutions.

2

Analysis & Interpretation

Clear, actionable engineering recommendations that can be practically implemented within existing operational constraints, ensuring effective and achievable solutions.

3

Corrective Actions

Post-implementation verification and reporting, including data to confirm improvements, a detailed report of findings, and follow-up meetings to review outcomes and next steps.

4

Verification & Reporting

Post-implementation verification and reporting, including data to confirm improvements, a detailed report of findings, and follow-up meetings to review outcomes and next steps.

4

Verification & Reporting

Our commitment

Vibremo is built on principles of technical integrity, hands-on collaboration, and continuous improvement. These values guide our work and the solutions we deliver.

Our Commitment

Vibremo is built on principles of technical integrity, hands-on collaboration, and continuous improvement. These values guide our work and the solutions we deliver.

We believe that understanding vibration behaviour in precision machinery is essential for sheet metal producers. It keeps processes stable, reliable, and high performing.

Our

Commitment

Vibremo is built on principles of technical integrity, hands-on collaboration, and continuous improvement. These values guide our work and the solutions we deliver.

We believe that understanding vibration behaviour in precision machinery is essential for sheet metal producers. It keeps processes stable, reliable, and high performing.

Working closely with our clients, we help ensure every part of the process - from hot rolling to finishing - optimises quality, productivity, and safety, while supporting sustainable manufacturing.

Working closely with our clients, we help ensure every part of the process - from hot rolling to finishing - optimises quality, productivity, and safety, while supporting sustainable manufacturing.

We believe that understanding vibration behaviour in precision machinery is essential for sheet metal producers. It keeps processes stable, reliable, and high performing.

Working closely with our clients, we help ensure every part of the process - from hot rolling to finishing - optimises quality, productivity, and safety, while supporting sustainable manufacturing.