top of page

Case Studies

Optimising Chain Tension in Roll Grinders

Vibremo performed precision retuning on a roll grinder headstock chain that was causing chatter marks on finished rolls through unwanted vibration.

Tuned Mass Damper - Grinding Wheel Spindle

Vibremo engineers installed Tuned Mass Dampers (TMDs) on a roll grinder wheel spindle.

Tension Leveller Chatter Mark Investigation

Vibremo conducted a full chatter mark investigation on a tension leveller and found the root cause issues.

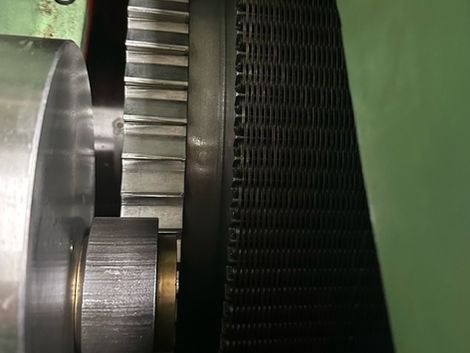

Modal Analysis on Roll Grinder

Learn how Vibremo used modal analysis to address vibration issues in a roll grinder, identifying resonances and recommending practical solutions to enhance roll quality.

Chatter Marks – Solution Confirmed! (3/3)

Vibremo conducted a full chatter mark vibration investigation and solved the problem on a 6-high cold rolling mill.

Effect of Steady Rest Changes (2/3)

Vibremo modified structural resonances of a roll grinder to eliminate chatter marks on finished rolls, by replacing curved steady rests with flat ones.

Marked Rolls in Cold Rolling Mill (1/3)

Chatter marks on aluminium strip from rolling mill traced to roll grinder issues. Find out about the investigation carried out by Vibremo.

Fan Imbalance on Roll Grinder

Vibremo conducted a vibration investigation on a roll grinder that was experiencing unwanted vibration as a result of fan imbalance.

Case Studies

Need expert support for your vibration challenges?

Expert insights for your specific quality, productivity and sustainability needs.

bottom of page