Tuned Mass Damper - Grinding Wheel Spindle

- jm4155

- Jan 7

- 2 min read

Updated: 6 days ago

Background

Tuned Mass Dampers (TMDs) are a well established engineering system designed to prevent vibration build up at specific frequencies. They dissipate vibration energy as heat through high damping material and are very effective when it comes to resolving quality issues in sheet metal production.

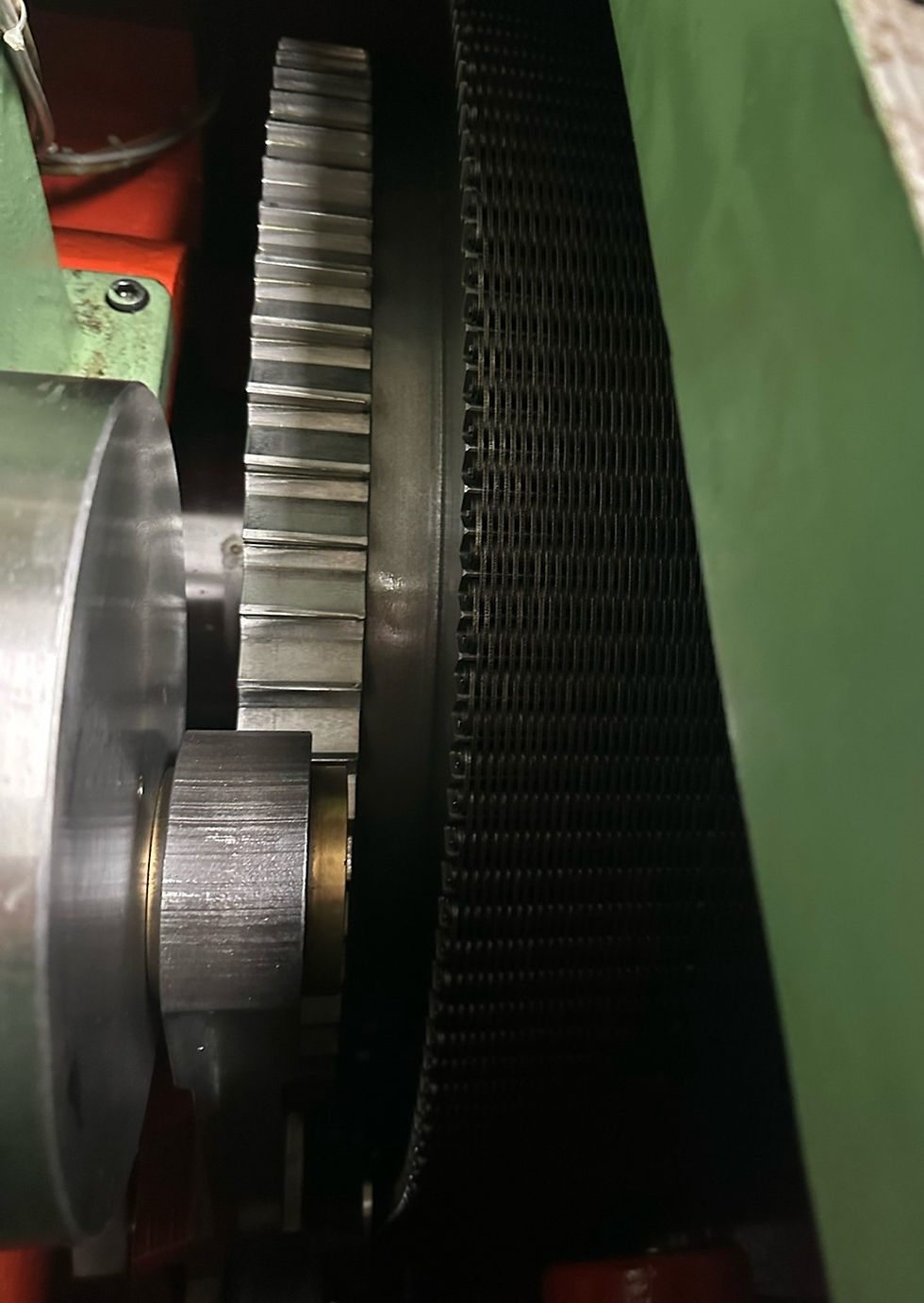

Earlier this year, Vibremo engineers installed 5 TMDs attached to wheel arbours in order to prevent the build up of persistent spindle chatter on a roll grinder.

Using advanced vibration analysis techniques and their practical expertise, our engineers installed and tuned the spindle dampers to the exact frequency of the spindle vibration – a task that required extreme levels of precision.

Measurements

Frequency response functions were obtained on the wheel spindle before the dampers were installed. There was clear evidence of a poorly damped, high amplitude spindle resonance at 195 Hz.

This poorly damped, high amplitude resonance was causing chatter marks on finished rolls, and previously made structural adjustments were unable to prevent vibration build up.

After measuring the undamped frequency, our engineers installed and tuned the spindle dampers on the grinder wheel head.

The frequency response function test was repeated on the spindle, and the resonance was found to have almost been completely eliminated. The amplitude was significantly lower and the damping was much higher.

Outcome

The Tuned Mass Dampers were successfully installed and the poorly damped peak was addressed. In order to confirm that the dampers were performing as required, operational measurements were taken on the wheel head of the grinder. There was no vibration in the spindle frequency range (130 – 250 Hz), indicating that the dampers were working as required.

Persistent vibration on precision machinery can often be very difficult to resolve. Strict surface finish requirements often mean that changing operational parameters isn't possible, and structural changes can be difficult and expensive to implement. In cases such as these, Tuned Mass Dampers are an effective solution, both in terms of cost and resolving the vibration issue.

Vibremo engineers have lots of experience installing and precision tuning Tuned Mass Dampers on roll grinders and our clients are delighted when they see how effective they can be.