Tension Leveller Chatter Mark Investigation

- Jan 7

- 2 min read

Background

A tension leveller is a key component in the finishing line during sheet metal production. They correct shape defects in the strip and ensure the finished coil is well levelled and flat.

Vibremo was recently contacted by one of our regular clients who had been experiencing chatter mark issues on one of their tension levellers for some time. In order to combat the quality issues, the operators were forced to run the machine at lower speeds, resulting in a decrease in productivity.

Using advanced vibration analysis techniques and our practical expertise, we determined that the unwanted vibration had two main sources. The first was the result of a poorly damped resonance caused by a weak connection at one of the levelling cartridges, and the second was a gear defect in one of the exit bridle roll drives.

Investigation Findings

Vibration measurements taken on the levelling section showed clear high amplitude vibrations, most prominent on the top centre cartridge, at frequencies that matched chatter marks observed on the output strip.

Resonance testing carried out on the cassette and the machine frame showed a clear difference in responses, indicating that there was a weak connection between the two components.

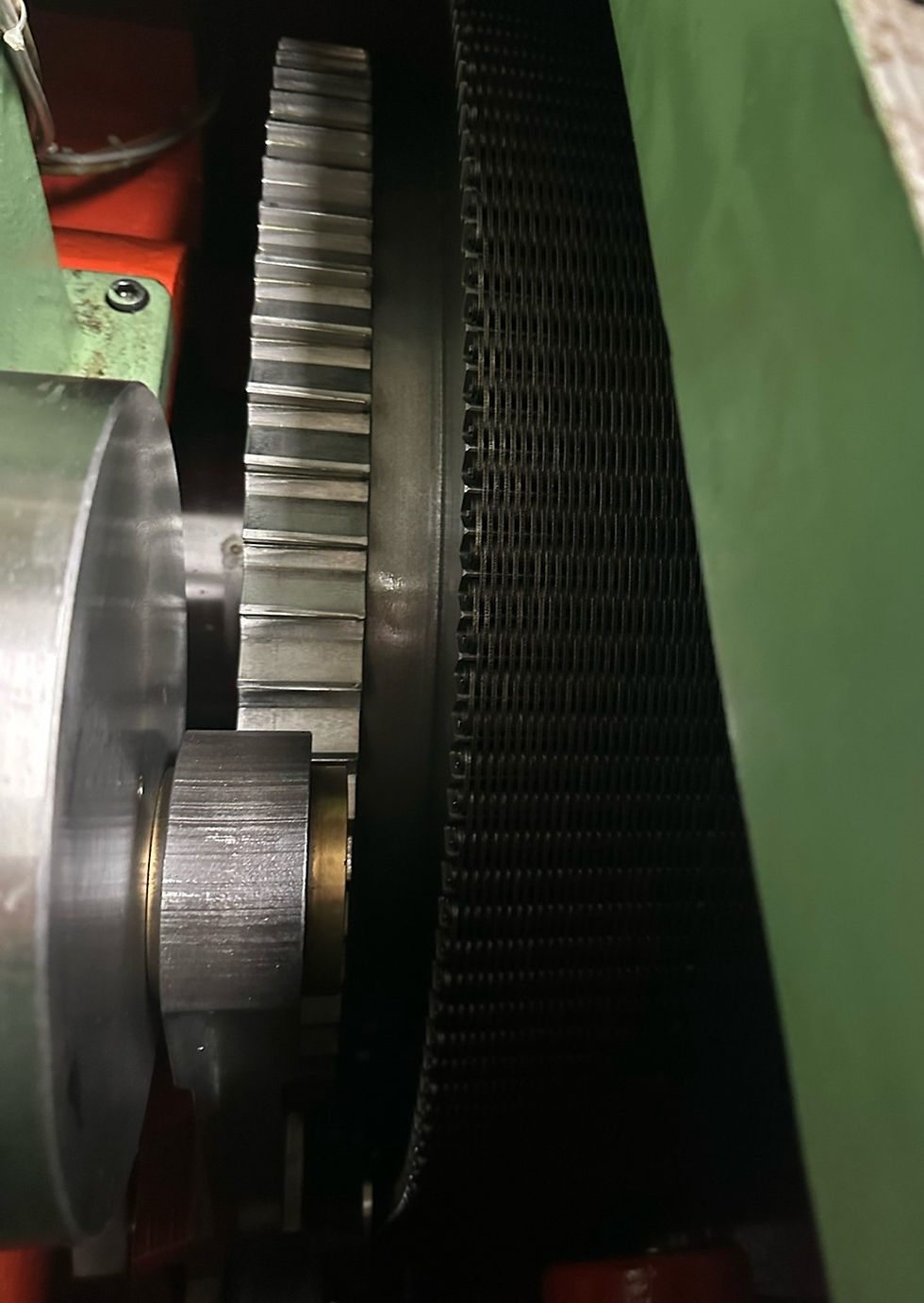

Measurements on the exit bridle rolls also showed high amplitude vibrations, particularly on the 3rd bridle roll. These high amplitude vibrations matched the gear mesh frequency of the drive system driving that roll, giving clear evidence that a gear defect existed.

Outcome

After the submission of the report and findings, the client replaced the hydraulic nut system that controlled the connection at the top centre cartridge. They immediately noticed an improvement and reported that they were able to operate the leveller at higher speeds with fewer chatter mark occurrences.

In order to completely eliminate the chatter mark issue, the client has scheduled to have the defective exit bridle roll gear replaced.

Conclusion

“We have replaced the hydraulic nut connection system at the cassette #2. Now operating at higher speeds and seeing less chatter marks. Gear repair scheduled.”

Section Lead - Levelling

This case study highlights the importance of detailed, in-person vibration measurements. We work with our clients to identify structural weaknesses where they exist and where they are causing quality issues.

As a result of the tension leveller investigation, we identified the root cause of the issue for the client and they were able to operate the leveller at higher speeds, whilst experiencing fewer quality issues. These changes resulted in an increase in productivity and a reduction in operating cost.