Optimising Chain Tension in Roll Grinders

- Jan 7

- 2 min read

Updated: Jan 9

Background

Vibremo engineers identified a persistent vibration issue in a roll grinder as the root cause of chatter marks observed on finished backup rolls. These imperfections directly impacted the quality of the aluminium sheet produced by a cold rolling mill, leading to similar markings on finished coils.

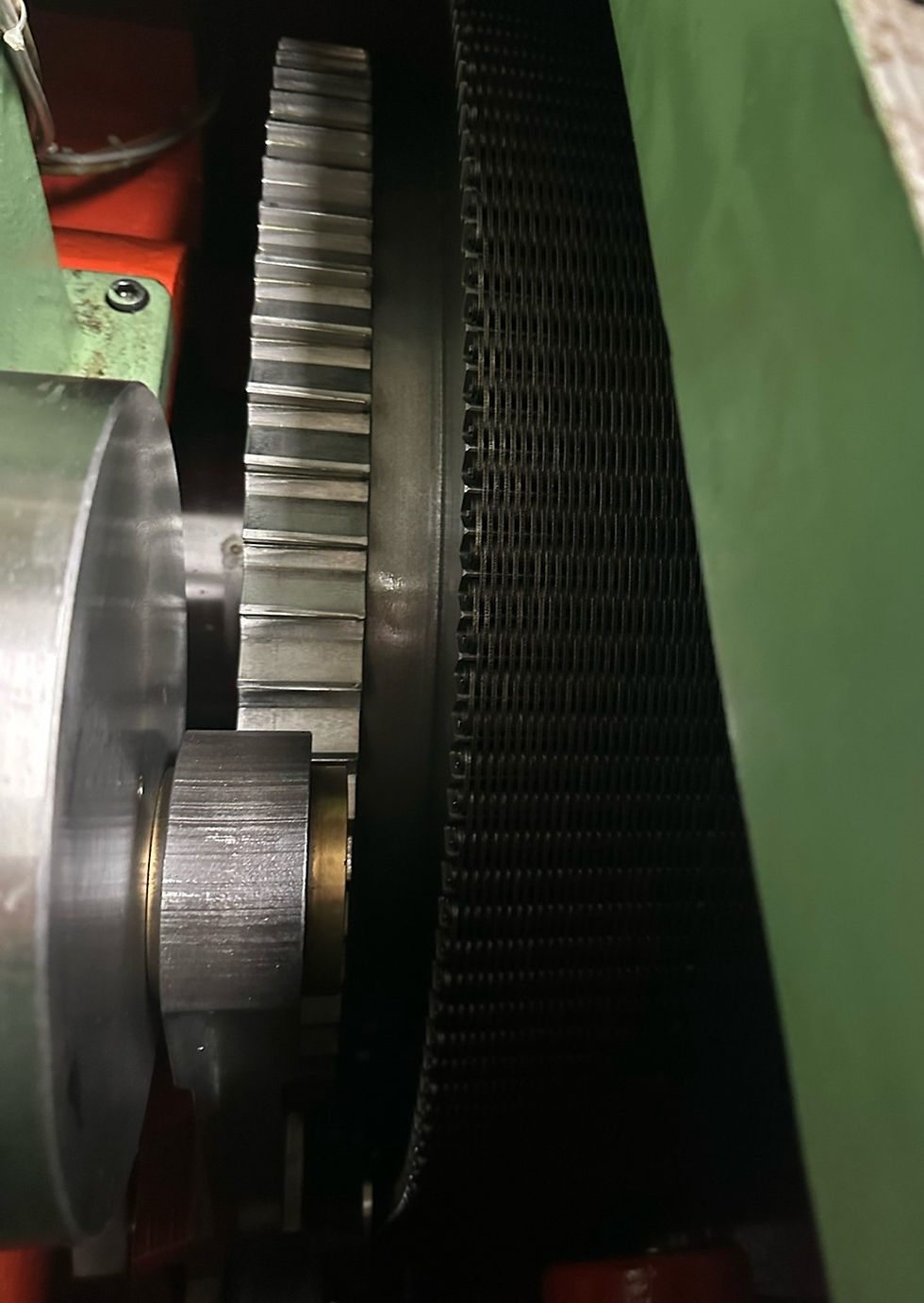

Using our expertise in vibration analysis, we traced the source of the issue to the headstock chain - a critical component of the drivetrain system responsible for transmitting mechanical power from the motor to the roll.

Finding an effective solution to eliminate these vibrations became a priority in order to improve grinding performance, restore the quality of the rolls, and ultimately lead to satisfactory output aluminium sheet.

Solution

Our engineers have many years experience working on these types of issues, and they knew that one method of minimising the effect of unwanted vibration coming from a chain was to adjust its tension to the ideal tuning. This was done by rotating the grinder headstock chain tensioner.

We determined the optimal adjustment by carrying out running light tests, a specific experiment performed with only the roll turning, which resulted in a significant reduction in vibration levels.

Outcome

To confirm the positive effect obtained by tightening the chain, our team performed more vibration measurements at various roll speeds during grinding operation.

Vibration levels at the chain frequency were reduced at all tested roll speeds after adjusting the chain tension, with a maximum reduction of close to 70%!

It has been reported that the rolls ground after this investigation are now chatter-free, significantly improving the quality of rolls sent to the rolling mill and the output strip.

This case study highlights the critical role of optimising chain tension in roll grinders to reduce vibration levels and improve roll quality. The significant improvement in grinding performance demonstrates the value of regular testing, proactive maintenance, and targeted adjustments. Addressing these mechanical issues early not only prevents defects but also boosts overall production efficiency and product reliability.